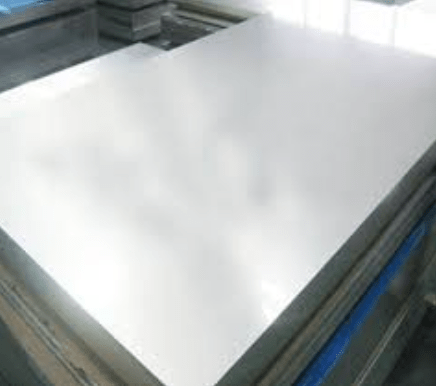

Customizing stainless steel 409 sheets and plates involves tailoring them to specific requirements, whether in dimensions, surface finish, or other properties. Stainless steel 409 sheets and plates is a ferritic stainless steel commonly used in automotive exhaust systems and applications where corrosion resistance is essential. Here are some customization options:

Dimensional Customization:

- Thickness: Adjust the thickness of the sheets or plates based on the structural requirements of your application.

- Width and Length: Customize the width and length according to your needs.

Surface Finish:

- Finish Type: Choose the desired surface finish, such as a bright annealed finish, matte finish, or a specific polish level.

- Texture: Depending on the intended use, you might want a smooth, polished or textured surface.

Cutting and Shape:

- Cut-to-Length: Sheets and plates can be cut to the required length, reducing waste and facilitating easier installation.

- Custom Shapes: Waterjet or laser cutting can create custom shapes or designs.

Edge Profiles:

- Edge Conditioning: Specify the type of edge you need, such as a straight edge, bevelled edge, or rounded edge.

Corrosion Resistance:

- Surface Treatment: Apply additional coatings or treatments to enhance corrosion resistance in specific environments.

- Passivation: Treat the stainless steel to remove contaminants and enhance its corrosion resistance.

Testing and Certification:

- Quality Control: Request specific quality control measures or testing procedures to ensure the product meets your standards.

- Certification: Depending on your industry, you may require specific certifications (e.g., ASTM, ASME) for the materials.

Packaging:

- Custom Packaging: Specify how you want the sheets or plates to be packaged to ensure they arrive in optimal condition.

Special Requirements:

- Special Alloys: If your application demands specific alloying elements, discuss the possibility of custom alloy compositions.

- Heat Treatment: Specify any required heat treatment processes for enhanced mechanical properties.

Quantity and Lead Time:

- Batch Sizes: Discuss the feasibility of producing customized batches based on your project requirements.

- Lead Time: Consider the production lead time, especially if you have tight project timelines.

Documentation:

- Material Certificates: Request material certificates or test reports to verify the composition and properties of the stainless steel.

Work closely with your supplier or manufacturer to communicate your specific needs and ensure you receive a product that meets the required standards and specifications.