Pigging is a process of using a solid object called a “pig” to clean and maintain pipelines. It is widely used in the paint industry to improve efficiency, reduce waste, and enhance product quality.

How a pigging system works

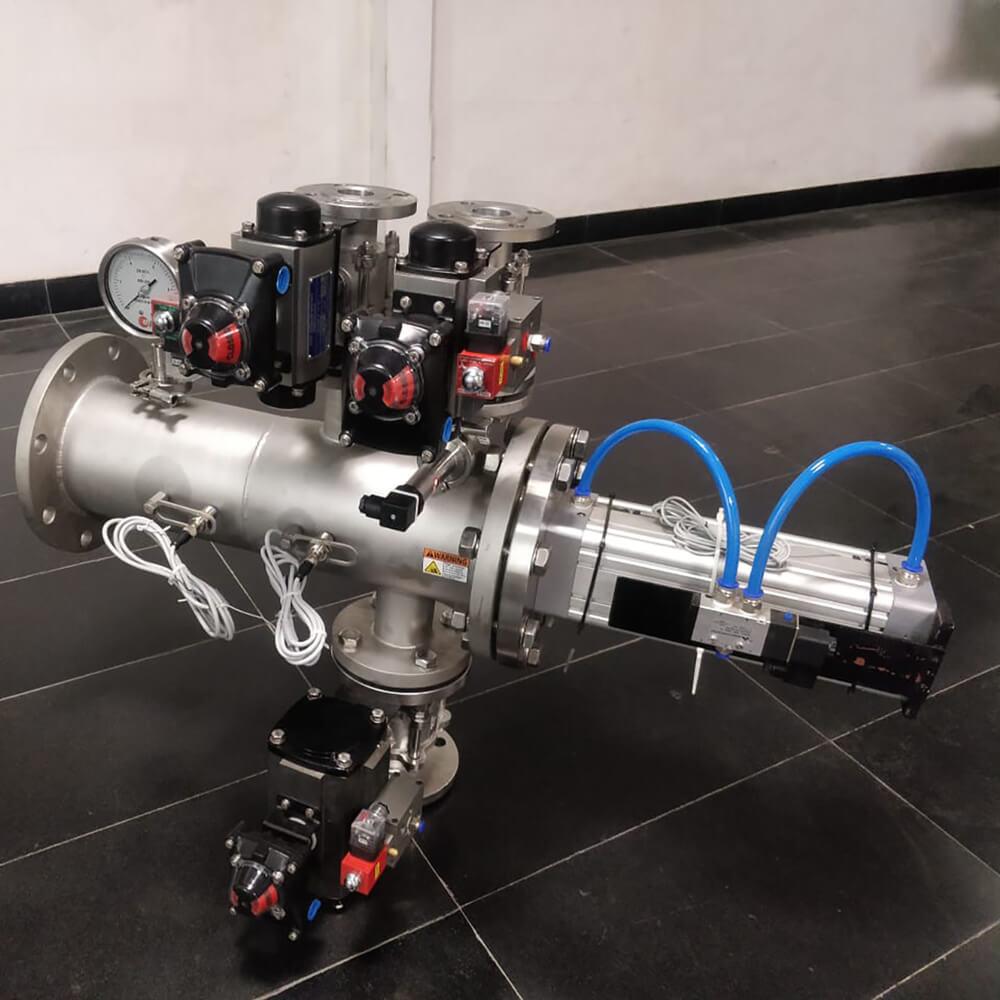

A pigging system for paint industry typically consists of a pig launcher, a pig receiver, and a pig. The pig launcher is a device that is used to insert the pig into the pipeline. The pig receiver is a device that is used to remove the pig from the pipeline. The pig is a solid object that is slightly larger in diameter than the pipeline. It is made of a variety of materials, such as polyurethane, foam, and rubber.

To operate a pigging system, the pig is first inserted into the pig launcher. The pig launcher is then sealed and pressurized. The pressure forces the pig down the pipeline. As the pig travels through the pipeline, it cleans and maintains the pipeline walls. The pig also removes any residual paint or other materials from the pipeline.

Benefits of using a pigging system in the paint industry

There are many benefits to using a pigging system in the paint industry, including:

Improved efficiency: Pigging systems can help paint manufacturers to improve their efficiency by reducing downtime associated with cleaning and changeovers.

Reduced waste: Pigging systems can help paint manufacturers to reduce waste by recovering up to 99.5% of paint from pipelines. This can lead to significant cost savings.

Enhanced product quality: Pigging systems can help paint manufacturers to enhance product quality by ensuring that pipelines are clean and free of contamination. This can lead to a reduction in product rejects and recalls.

Improved safety: Pigging systems can help paint manufacturers to improve safety by reducing the need for workers to enter pipelines for cleaning and maintenance.

Example of a pigging system in the paint industry

One example of a pigging system in the paint industry is the HPS Pigging System. The HPS Pigging System is a fully automated system that uses specialized pigs to recover residual paint from pipelines after transfer sequences have taken place.

The HPS Pigging System works by first inserting a pig into the pipeline. The pig is then propelled through the pipeline by the pressure of the paint. As the pig travels through the pipeline, it scrapes the walls of the pipeline and removes any residual paint. The residual paint is then recovered by the pig and transported to a storage tank.

The HPS Pigging System can be used to recover a variety of paints, including water-based paints, solvent-based paints, and varnish. It can also be used to recover paints that contain a variety of pigments and additives.

Conclusion

Pigging systems are a valuable tool for paint manufacturers. They can help paint manufacturers to improve efficiency, reduce waste, enhance product quality, and improve safety. If you are considering using a pigging system in your paint manufacturing operation, I encourage you to contact a pigging system supplier to learn more about the benefits of pigging and to find a system that is right for your needs.